-

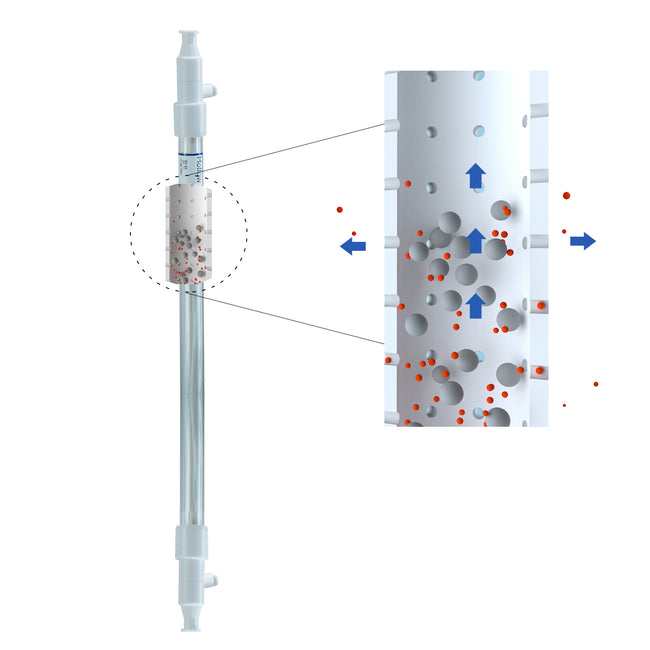

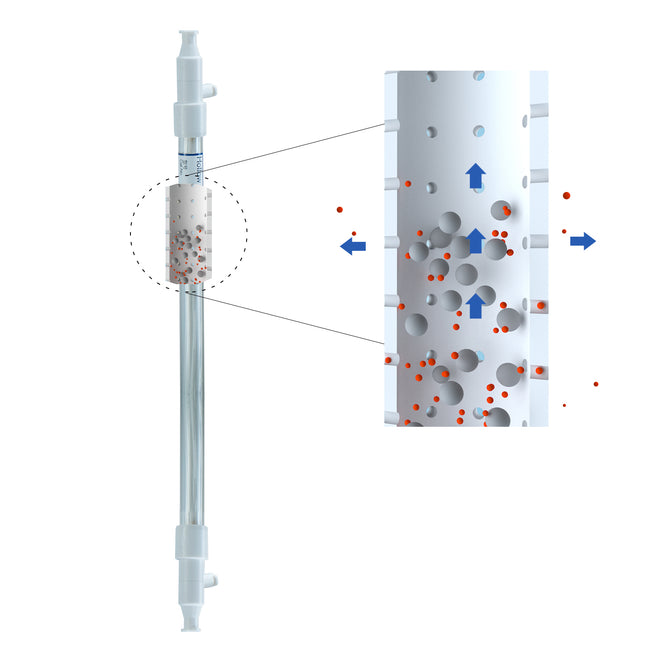

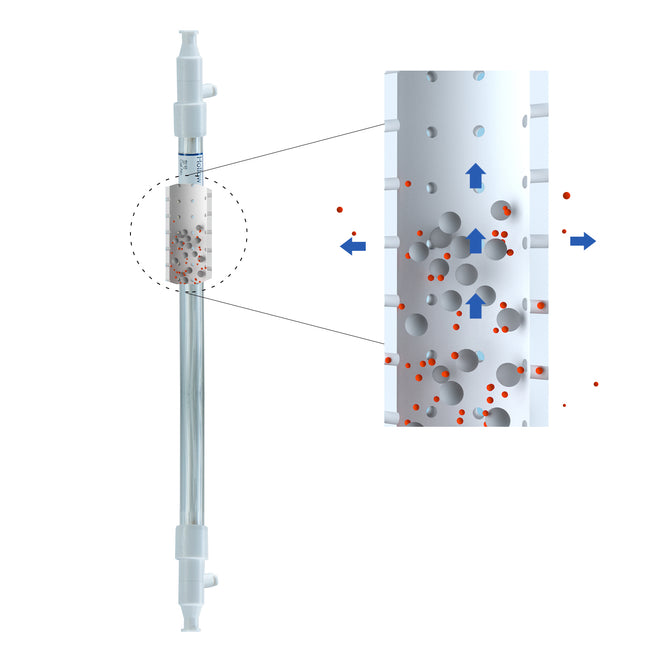

COBETTER 0.5mm Mini Hollow Fiber TFF mPES Membrane

Membrane PESMWCO 100/300/500/750kDaFiltration Area 28cm²/ 56cm²Package 1/pk -

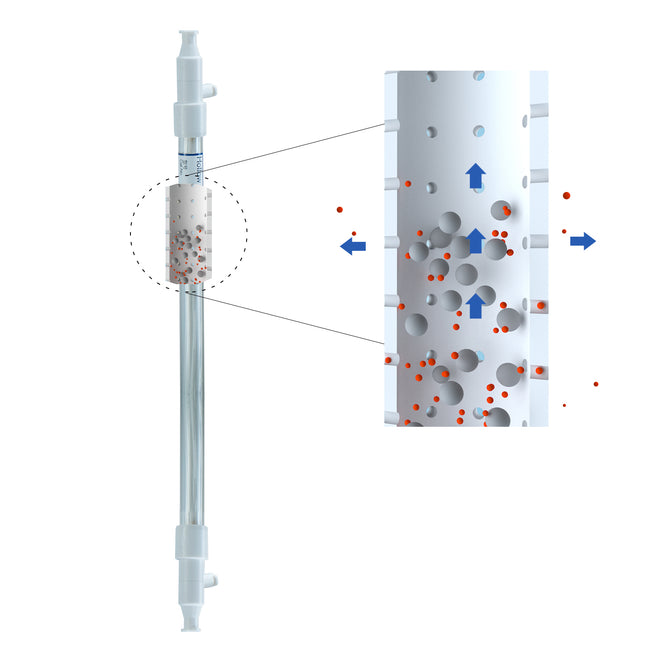

COBETTER 1mm Mini Hollow Fiber TFF mPES Membrane

Membrane PESMWCO 100/300/500/750kDaFiltration Area 28cm²/ 56cm²Package 1/pk -

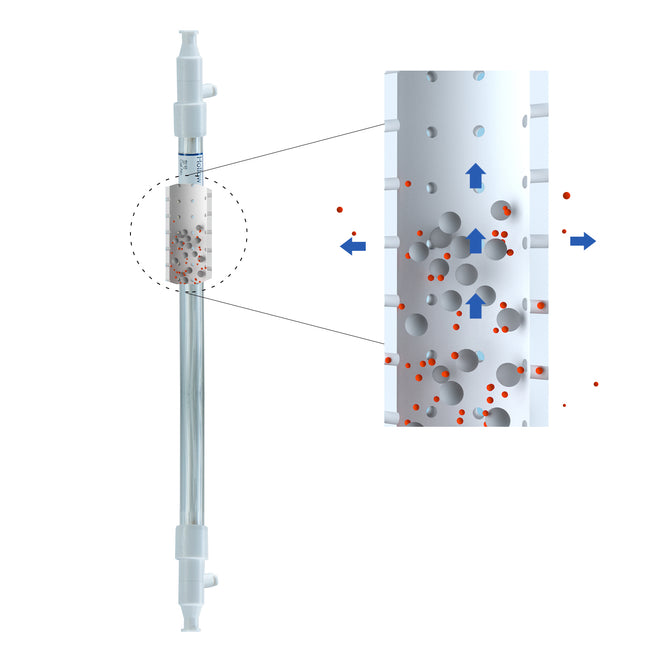

COBETTER 0.5mm MiniLab Hollow Fiber TFF mPES Membrane

Membrane PESMWCO 100/300/500/750kDaFiltration Area 118cm²/ 236cm²Package 1/pk -

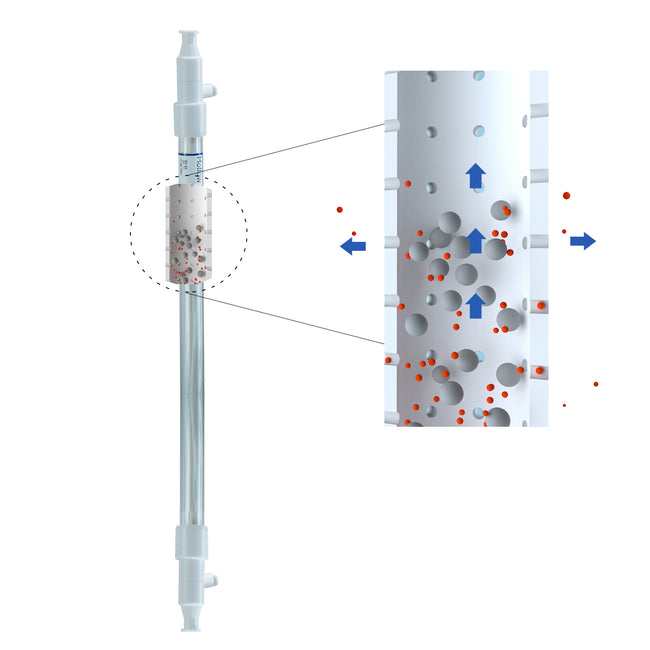

COBETTER 1mm MiniLab Hollow Fiber TFF mPES Membrane

Membrane PESMWCO 100/300/500/750kDaFiltration Area 94cm²/ 188cm²Package 1/pk -

COBETTER 0.5mm Lab Hollow Fiber TFF, mPES

Membrane PESMWCO 100/300/500/750kDaFiltration Area 236cm²/ 471cm²Package 1/pk -

COBETTER 1mm Lab Hollow Fiber TFF, mPES

Membrane PESMWCO 100/300/500/750kDaFiltration Area 170cm²/ 340cm²Package 1/pk

Coetter hollow fiber filters are available with a broad range of sizes for easy scale-up from small volume R&D applications, small volume pilot to commercial production.

Features

· A broad range of sizes for easy scale-up

· Hydrophilic modified PES membrane provides low protein binding

· Cost-efficient and time saving

· Quick installation and easy operation, no holder required

Applications

· Purification, concentration and diafiltration of viral vector

· Clarification of cells and bacterial from fermentation broth

· Clarification of cell lysates or cell debris

· Concentration and diafiltration of proteins

· Perfusion applications

How to use a hollow fiber membrane filter?

Module Preparation

For lab and pilot applications, you will need a pump, a feed tank, a permeate collection tank, pressure gauges and valves and suitable tubing and connectors.

Cobetter hollow fiber modules made with hydrophilic modified PES membrane contain glycerin to preserve the pore structure. Glycerine is water soluble and easy to rinse out.

- Rinse out glycerine with DI water with an inlet pressure of 2-5 psi, the flushing volume should be greater than 20L/m².

- Drain module and perform module integrity test.

Note: If sanitization is necessary, use 0.1N NaOH solution as a disinfectant.

Module Integrity Test

All hollow fiber modules are integrity tested at our site. However, Cobetter highly recommends an integrity test before use. Cobetter recommends two test methods, one of which may be applied according to actual operating conditions.

- Diffusion Flow Method

- Pressure Retaining Method

Processing Buffer Equilibrium

The purpose of flushing hollow fiber modules with buffer is to ensure that the pH and salt ion conditions of the system are as similar as possible to the initial state of the sample, so as to reduce pollution and product loss.

Cleaning after Use

The hollow fiber modules must be cleaned before storage and reused by flushing with buffer or DI water, and then washed with appropriate sanitizing agent. 0.5M NaOH solution may be used to circulate for 30 min at 20-40°C.

Hollow Fiber Storage

The hollow fiber modules may be stored in 0.1N NaOH solution. For long-term storage between 1-12 months, it is recommended to be stored under refrigeration at 4°C.

Related Articles

The Applications of Hollow Fibers in Upstream Bioprocessing

mRNA Vaccine Manufacturing Strategy 1 --Plasmid DNA Production

mRNA Vaccine Manufacturing Strategy 2 - IVT in mRNA Production

The Application of Hollow Fiber Filter in Plasmid and Virus Manufacturing

Cobetter Minilab TFF Tangential Flow Filtration System

Application of Ultrafiltration in Recombinant Human Insulin Production

- Hollow_Fiber_Filters Download