-

-20%

-20%COBETTER 1m Lifemeta™ STT Platinum Cured Silicone Tubing 5/10 per pk

Package 5/pk or 10/pk

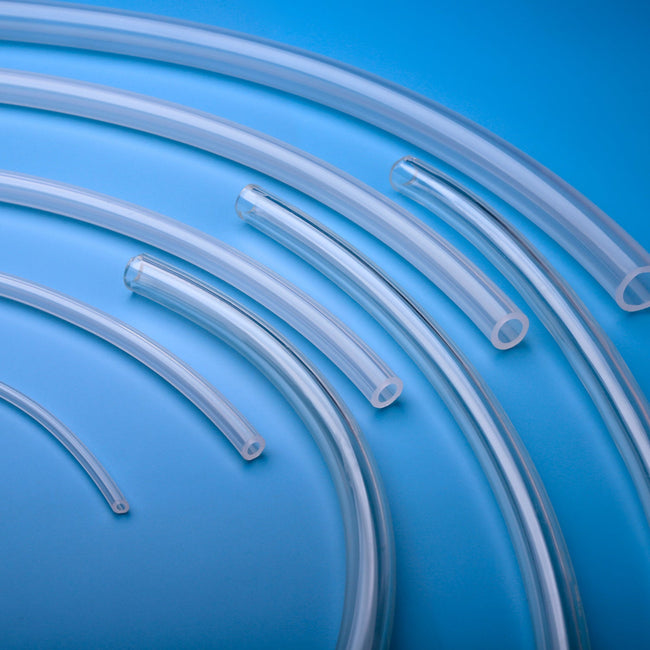

Lifemeta™ STT Platinum Cured Silicone Tubing

Cobetter Lifemeta™ STT Platinum Cured Silicone Tubing is platinum-cured, which provides exceptional high-temperature resistance and reduces the potential for leachables, making it a reliable choice for critical fluid transfer.

Features

· Low extractable for the transfer of critical fluids

· Smooth hydrophobic inner surface.

· Excellent biocompatibility and chemical compatibility can tolerate a variety of solutions

· Robustness-Excellent performance in tensile strength, burst strength and sterilization stability

Applications

· Non-sterile coils to build your own assemblies

· Part of pre-sterilized single-use systems

· Fluid transfer

Lifemeta™ STF Thermoplastic Elastomer Tubing for Fluid Transfer

Cobetter Lifemeta™ STF tubing, extruded from pharmaceutical grade thermoplastic elastomer (TPE) material, has excellent pumping performance and smooth inner bore and is superior to silicone and PVC tubings for many applications. It can be heat-sealed and welded to maintain sterile conditions.

Features

· Exceptional cell growth results;

· Highly resistant sealable and weldable tubing;

Applications

· Media and buffer processing

· Fermentation

· Cell harvest

· Laboratory research

· Vaccine production

Lifemeta™ ST8H High Pressure Silicone Tubing

Cobetter Lifemeta™ ST8H high pressure silicone tubing is a high-quality, cost-effective fluid transfer solution. It can be used to increase the flow rate during the production process and reduce the liquid transfer time. ST8H high pressure silicone tubing is the optimal choice for single-use applications such as TFF, virus filtration, inline integrity testing of filtration assemblies, and high volume fluid transfer.

Features

· Allows for processing at higher flow rate

· Full vacuum capabilities on most sizes

· Flexible, translucent and durable

· Excellent resistance to compression set

· Good kink resistance

· Less particle shedding when cutting

Applications

· TFF

· Virus filtering

· Online integrity testing of filter components

· High volume fluid transfer

· Laboratory fluid transfer applications

· Single-use tubing assemblies

Lifemeta™ ST5P Pt-cured Silicone Pump Tubing

Cobetter Lifemeta™ ST5P Pt-cured silicone pump tubing can be used in process applications such as ultrapure liquid transfer in production, aseptic filling, packaging and other single-use systems. Fluid transmission is mainly carried out through a peristaltic pump, which reduces the risk of fluid contacting any part of the pump body. Good wear resistance can reduce damage to the outer wall of the tubing, thereby improving the overall transmission efficiency of the filtration system.

Features

· Excellent peristaltic pump life

· The operating life in the pump is over 100 h

· Excellent wear resistance, low flaking

· Good chemical compatibility

· Excellent tensile strength

· Smooth inner wall, excellent fluidity

· Low adsorption performance

Applications

· Aseptic filling and dispensing systems

· Diagnostic equipment

· Vaccine production

· Biological filtration and fermentation

· Bioreactor applications

· Shear sensitive fluid transport

Lifemeta™ Tubing Assemblies

Single-use tubing assemblies are critical for transfers between single-use and hybrid systems. With our tubing assemblies, you can easily connect multiple containers, vessels and process lines in one system. The extension set is available in a variety of tubing sizes and lengths to meet your fluid transfer needs.

Features

· Ready to use, saving time and reducing costs

· Streamline the collection and transfer of samples

· Minimizing the risk of cross-contamination

· Custom assemblies are available

Applications

· Buffer and media transfer

· Collecting samples

· Media filtration

· Removal of liquids from bioprocess

· Carboy Assemblies

· Peristaltic Pump Tube assemblies

Quality Assurance

· ISO™ 9001:2015 quality management system

· Manufactured in ISO Class 7 clean area

· Leak testing

· ADCF raw materials, meet the FDA Indirect Food Additive requirements cited in 21 CFR 177–182

· Meet the requirement of USP <87> In Vitro Biological Reactivity Test

· Meet the criteria of the USP <88> Biological Reactivity Test for Class VI plastics

· Aqueous extraction contains < 0.25 EU/mL as determined by Limulus Amebocyte Lysate (LAL), USP <85>

· Particulate matter in the product eluent meets the requirements in USP <788> for large volume parenterals

· Verify gamma irradiation dose of sterile packaging according to ISO 11137